- 01.

FOR WORST-CASE

SCENARIOSAs TYR™ is designed explicitly for those spearheading high-threat operations, the layup has significantly increased multi- and edge-hit performance, in addition to complete contact-shot protection.

- 02.

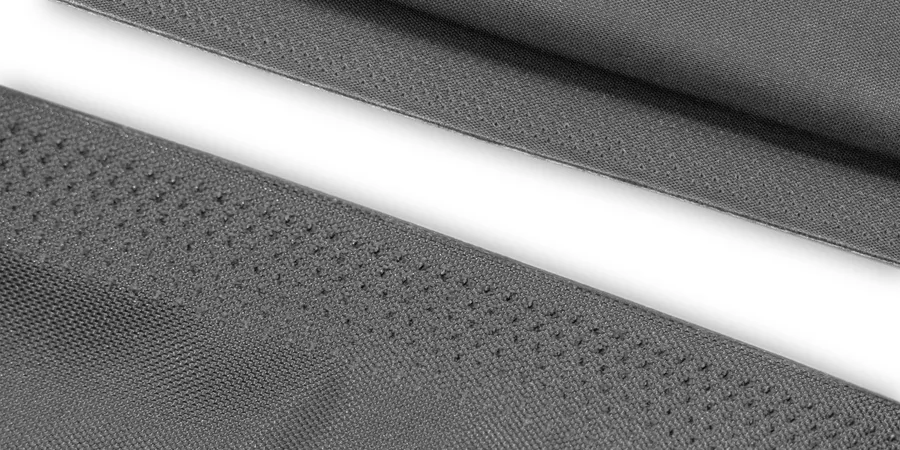

SOFT ARMOUR

STRIKE-FACEDesigned to stop a projectile's rotational energy, our mixed-weave strike-face works in tandem with the unidirectional laminates underneath to engage more ballistic material, decreasing the number of layers perforated.

- 03.

BUILT-IN

ANTI-TRAUMACombining early bullet deformation with a built-in CARNA™ anti-trauma liner and ballistically reinforced CARNA™ AT panels, the blunt force trauma is decreased by 50-60% compared to traditional soft armour solutions.

The TYR™ layup has explicitly been designed for short wear durations and extreme close-range trauma mitigation against small-calibre munitions for those spearheading CQB/CQC tactical situations such as point-men, shield carriers and counter-terror units.

By combining a unique blend of materials and high-quality fibers, the TYR™ layup combines the most cutting-edge ballistic materials on the market to perfectly orchestrate every stage of the ballistic event, layer by layer, all while being remarkably flexible, allowing you to operate effectively in high-threat situations.

VPAM PM Ed. 3, Annex 6.6.2

3 shots of 9x19mm DM41 FMJ get fired at 415 m/s with 25mm spacing in an equilateral triangle.

DISCLAIMER: These illustrations are meant as a visual aid and are not drawn to conform to their respective standards.

We carry out an additional test beyond the scope of VPAM BSW 2006 based on the VPAM PM standard for all of our layups.

The test is usually intended for hard armour and calls for three shots to be placed in an equilateral triangle spaced up to 5, or at a minimum of 3 caliber diameters apart for the tested threat.

We use a standard spacing between each round of 25 mm to test against a 'worst-case' scenario.

VPAM BSW 2006, Annex 6.10

1 shot of 9x19mm DM41 FMJ gets fired at 415 m/s, impacting 25mm from the edge of the panel.

DISCLAIMER: These illustrations are meant as a visual aid and are not drawn to conform to their respective standards.

Specifically for protection classes 1 through 3, the VPAM BSW 2006 calls for an extra edge shot to be tested without any backface deformation measurements necessary.

The standard calls for the hit to be 30 ±5 mm from the outer edge of the sample and at least 75 mm from any corners.

We carry out our test edge shots 25 mm from the edge.

VPAM BSW 2006 Annex 3.1

3 shots of 9x19mm DM41 FMJ get fired at 415 m/s impacting 75mm apart in the pattern of an equilateral triangle.

DISCLAIMER: These illustrations are meant as a visual aid and are not drawn to conform to their respective standards.

Classes 1 through 3 get shot 3 times per test sample in an equilateral triangle pattern with 75mm between each vertex.

Backface deformation is measured after each shot, and the measured deformation has to be ≤22 mm for each shot.

For threat levels 4 and 5, backface deformation is not measured.

All tests are carried out on the same 25x25 cm commercial sample panel.

If you want to test a panel for yourself, discounted sample panels are available here.

NOTE: Illustrated with body-side at the top, descending downwards towards the strike-face at the bottom.

The above widget only illustrates layup composition and is not an accurate representation of layer count or relative thickness.

DEDICATED soft armour STRIKE-FACE

Utilising a unique mixed weave style as a soft armour strike-face by combining the ballistic effectiveness of an open satin weave with the structural integrity of a plain weave in a merged woven matrix allows the TYR™ layup to effectively double the early projectile impact deformation.

The final weave prevents pull-through of the fibers and works in conjunction with the hybrid core to engage more total material and slow the projectile's rotational energy. This catches it more effectively and, as such, dissipates energy significantly faster than pure unidirectional laminates or plain woven weaves for the strike-face.

These stopping mechanisms lead to earlier mushrooming of the projectile, meaning fewer layers are perforated, ultimately leading to a significant reduction in trauma to the wearer without negatively impacting flexibility.

AN ALTERNATING HYBRID CORE

Making up the bulk of every TYR™ panel is a hybridised core of Twaron® microfilament laminate combined with cutting-edge unidirectional Spectra Shield® fibers working in tandem to protect against advanced handgun threats.

Lighter projectile threats, such as those found natively at the NIJ 0101.07 HG2 and VPAM 3 levels, will rarely perforate a TYR™ panel beyond the strike-face, allowing the remainder of the energy to be effectively dispersed in the laminates beneath.

In addition to these common threats, the TYR™ layup is also capable of handling the FBI and DEA special threats, such as the Five-Seven SS195 LFHP, SS197 Hornady and the 85 gr FMJ Tokarev.

NEXT-LEVEL TRAUMA MITIGATION

The TYR™ layup features an upgraded ballistic variant of our CARNA™ strike-face to increase the axial energy dispersion after the projectile has been caught.

By adhering high-density, tightly woven Twaron® fibers to the CARNA™ AT panels, energy dissipation is increased throughout the entire ballistic stack without severely hindering flexibility or adding much additional weight.

Every TYR™ panel contains two ballistically reinforced CARNA™ AT panels alongside a backer of our impact-hardening CARNA™ polymer for increased comfort and superior impact mitigation.

Providing a 50-60% decrease in blunt force trauma compared to traditional HG2 / HG2 & VPAM 3 inserts, the TYR™ combines the dedicated strike-face, hybrid core layup, Twaron® laminated CARNA™ AT, and CARNA™ anti-trauma padding to ensure you'll be able to keep your composure and return fire in the event a projectile strikes you.

BUILT FOR WORST-CASE SCENARIOS

While all our ballistic layups provide edge-case protection, the TYR™ layup steps it up a notch.

By conforming to the VPAM's optional multi- and edge-hit standards, you can feel safe knowing that you'll be protected even if a projectile hits the edge of your armour or you're confronted with a salvo of projectiles impacting near each other.

Furthermore, the TYR layup provides complete contact-shot protection, so you can stay safe even when moving single file through an enclosed area when spearheading.

INDUSTRY-LEADING WEAR RESISTANCE

We use a unique cover material made of lightweight, abrasion-resistant polyamide face fabric coated with a durable water-repellent. Our internal liner is TPU-based and features UV-blocking pigment to protect the ballistic materials from photooxidation caused by the sun's UV radiation, ensuring consistent performance throughout the insert's lifespan, no matter the environment.

Our two-stage sealing process ensures that every insert is safe from hydrolytic degradation from water, vapour, or general moisture. We accomplish this by pre-sealing the edges in custom-made moulds for consistency, sealing potential leaks from material bending and creasing before finishing the edges using an ultrasonic welding process to fuse the cover materials together.

A CUT FOR EVERY OPERATOR

Thanks to our just-in-time manufacturing approach and the fact that all of our operations are handled in-house, we can offer a large selection of standardised cuts, layouts and sizes so that you can find just the right fit.

If you want a custom cut, please refer to our OEM/ODM page for more information.

- Areal Density 8.5 kg/m² (1.74 lb/ft²)

- Thickness 12 mm (0.47")

- ¹ Flexibility 520 N (116.9 lbf)

- Strike-Face Mixed-weave Twaron®

- CORE SPECTRA SHIELD® & Twaron® UD

- Mitigation Twaron® Reinforced CARNA™ AT

- Dispersion CARNA™ Urethane Polymer

- Resin Polyethylene, Rubber Elastomer & SBR Adhesive

- Thread Dyneema® SK75

- Cover DWR & TPU coated Polyamide

- Supplier Overview View Here

- Standards NIJ 0101.07 & VPAM BSW 2006

- Threat Rating HG2 & VPAM 3

- Country of Origin Denmark

- Warranty (Properties) 7 years

- Warranty (workmanship) 2 years

- ¹ Per ASTM D4032-92 PROUDLY MADE IN EUROPE

SPECIFICATIONS

TYR™ DATA

MATERIALS

GENERAL INFORMATION

THREAT OVERVIEW

| STANDARD | PLATFORM | PROJECTILE | WEIGHT | VELOCITY | VARIANCE | TRAUMA LIMIT |

|---|---|---|---|---|---|---|

| VPAM BSW 2006 | 9×19mm (FMJ² RN⁵ SC⁶) | 8g (124 gr) | 415 m/s (1360 fps) | ±10 m/s (±30 fps) | < 22mm (< 0.8") | |

| VPAM BSW 2006 | .357 Mag. (FMJ² CB⁸ SC⁶) | 10.2g (158 gr) | 430 m/s (1360 fps) | ±10 m/s (±30 fps) | NA | |

| VPAM BSW 2006 | 44 Rem. Mag. (FMJ² FN³ SC⁶) | 15.6g (240 gr) | 440 m/s (1445 fps) | ±10 m/s (±30 fps) | NA | |

| NIJ 0101.07 (NIJ 0123.00) | 9×19mm (FMJ² RN⁵) | 8g (124 gr) | 448 m/s (1470 fps) | ±10 m/s (±30 fps) | < 44mm (< 1.7") | |

| NIJ 0101.07 (NIJ 0123.00) | .357 Mag. (JSP¹) | 10.2g (158 gr) | 436 m/s (1430 fps) | ±10 m/s (±30 fps) | < 44mm (< 1.7") | |

| SPECIAL | .40 S&W (FMJ²) | 11.6g (180 gr) | 352 m/s (1155 fps) | ±10 m/s (±30 fps) | < 44mm (< 1.7") | |

| SPECIAL | .357 SIG (FMJ² FN³) | 8g (125 gr) | 448 m/s (1470 fps) | ±10 m/s (±30 fps) | < 44mm (< 1.7") | |

| NIJ 0101.07 (NIJ 0123.00) | .44 Mag. (SJHP⁴) | 15.5g (240 gr) | 436 m/s (1430 fps) | ±10 m/s (±30 fps) | < 44mm (< 1.7") | |

| SPECIAL | 7.62×25mm Tokarev (FMJ²) | 5.5g (85 gr) | 450 m/s (1475 fps) | ±15 m/s (±50 fps) | NA | |

| SPECIAL | 9×19mm +P+ (SXT) | 8.2g (127 gr) | 408 m/s (1340 fps) | ±15 m/s (±50 fps) | NA | |

| SPECIAL | 5.7×28mm SS195 (LFHP⁷) | 1.7g (27 gr) | 610 m/s (2000 fps) | ±10 m/s (±30 fps) | NA | |

| SPECIAL | 5.7×28mm SS197 | 2.6g (40 gr) | 545 m/s (1790 fps) | ±10 m/s (±30 fps) | NA |

¹ Jacketed Soft Point, ² Full Metal Jacketed, ³ Flat Nose, ⁴ Semi Jacketed Hollow Point, ⁵ Round Nose, ⁶ Lead Soft Core, ⁷ Lead Free Hollow Point, ⁸ Coned Bullet

WARNING: Certain powder, projectile and barrel length combinations will exceed the capabilities of this armour.

FREQUENTLY ASKED QUESTIONS

Yes. All of our listings are for a single item.

This allows you to pick out separate sizes and cuts depending on your usecase(s).

All of our products, including these, are manufactured by us in Denmark.

We take great pride in manufacturing everything in-house ourselves, using materials that are made in the EU or the US exclusively.

Almost.

We have shipping agreements with major providers to all NATO allied countries but do ship outside of NATO as well.

Under no circumstances can we ship goods to embargoed or sanctioned countries.

For a complete overview, please refer to our shipping page.

If you already own an armour carrier, please refer to the manufacturer or any documentation that came with it to find the appropriate size.

If this is your first armour purchase, please measure your chest circumference at the pecs. You can reference our sizing guide here for suggestions. Please note that the table changes depending on your product configuration at the top.

The most important aspect is that the insert covers your heart, lungs, kidneys and diaphragm. To ensure these vitals are covered, the insert should span from your sternum notch to 2 cm above your naval, and at its widest, should roughly equate to the distance between your pecs.

According to our warranty, 7 years.

This is an estimate we've set to ensure the protective properties are sustained throughout the insert's entire lifecycle. Proper maintenance and care will ensure the insert will provide protection significantly past its expiration date.

Not at all.

Many things can affect the durability of an insert, including materials, moisture exposure, heat, creasing and storage conditions.

Inserts with intact covers that have been properly cared for, and have not been subjected to unreasonable environmental or storage conditions, can provide like-new protection for years past their expiration.

That said, after an insert leaves our facilities, we can no longer guarantee its handling. Because of this, we've limited the recommended wear period to 5 years, and have a warranty which backs up this decision.

This depends on the round in question and the referenced standard.

We test our inserts against both the VPAM and NIJ standards, which call for different shot spacing and the number of rounds.

For VPAM threats, we shoot our panels 7 times. 3 of these hits have 75 mm spacing in an equilateral triangle in accordance with Annex 3.1 of VPAM BSW2006. The consequent 3 shots follow the same pattern but have 25 mm spacing to test true multi-hit performance. The last round is fired 30 mm from the edge of the panel, to ensure edge-hit protection.

For NIJ threats, the panel is shot 6 times with equal spacing between each shot and the edge of the insert in accordance with NIJ 0101.07.

Not officially, no.

Certification for either standard is incredibly resource intensive, requiring five-digit upfront laboratory fees, and for the VPAM specifically, close to hundreds of sample panels for testing.

It is something we are striving towards, however.

We do have all of our lots independently tested at NIJ or VPAM-accredited laboratories in the Netherlands and Germany against the required threats for each respective standard.

MAIL RESPONSES

WITHIN 24 HOURS

We're always available for questions and support.

SECURE PAYMENT GATEWAYS

All payments are handled through Paypal or Stripe.

WORLDWIDE

SHIPPING

We ship worldwide with a reliable network of partners.

30-DAY

RETURN PERIOD*

Wrong size? Wrong fit? Free size exchanges for 30 days.

* Please refer to our return and refund policy for more information.

We care enormously about bringing you the best solution for your use case. If you have any questions, concerns or feedback, don't hesitate to get in touch with us at the e-mail below.