OEM/ODM SERVICES

We provide OEM/ODM cutting, sewing, sealing and labelling services for soft ballistics with no minimum order quantities for existing and new brands wishing to enter the industry that cannot manufacture in-house.

This includes body armour retailers, distributors and webshops.

CUSTOM LAYUPS & MATERIALS

Our existing product layups are available for use if you do not wish to or cannot design your own. Alternatively, we provide ballistic consulting if you're looking to stop a specific threat or reach a particular trauma level against a given threat profile at no additional charge.

Practical testing can be carried out inexpensively thanks to our close partnerships with ranges and testing laboratories if you don't wish to be in charge of this.

Minimum order quantities will apply if we have to import or acquire non-stocked materials. Don't hesitate to get in touch with us for a complete list of our continuously stocked materials.

CUTTING CAPABILITIES

Our entire cutting and processing workflow is entirely automated.

Thanks to this, we can process complex shapes and cuts using CAD/CAM with sub-millimetre precision, guaranteeing that every manufactured product has negligible variability.

A further advantage is that we can offer these services with no minimum order quantities, allowing you to scale from a single sample for testing to full-scale production.

Please refer to our 'Technical cutting details' section for specifics.

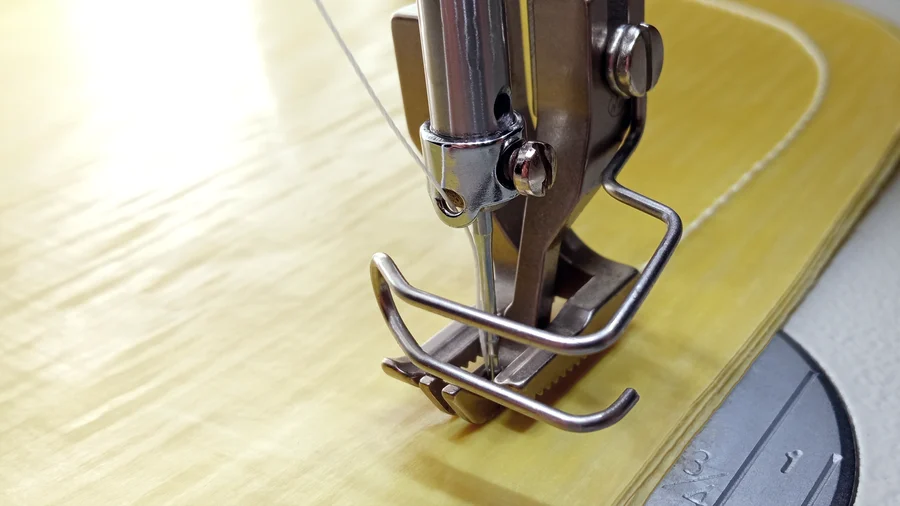

SEWING CAPABILITIES

We use powerful sewing machines and made-to-order carbide needles to ensure clean material penetration for stitching operations. Depending on material type, density and lamination used, we can sew through 20-40 layers of unidirectional ballistic material with appropriate multi-step bartacking, be it for trauma reduction, layer adhesion or increasing multi-hit performance.

For all stitching operations on ballistic layups we utilise 840dTex Twaron® and Dyneema® SK75 sewing threads with respective breaking strengths at 215 and 120 newtons.

We have no layer limitations on woven ballistic fabrics.

Please note that we do not offer custom design/manufacturing services of non-ballistic goods, such as platforms, carriers or pouches with an undesignated end user, or for resale.

In practice, this means we exclusively make custom non-ballistic solutions for law enforcement, military and security personnel, but not for redistribution or resale to the general public.

Exceptions may apply.

Please refer to our contact form if you're interested in becoming a distributor for our existing non-ballistic products.

SEALING CAPABILITIES

As standard, every soft insert features a cover consisting of a black 78 Dtex polyamide fabric weighing in at 150 g/m², with an outer DWR coating and an internal TPU laminate.

We seal using a two-step process: a mix of laminated thermoplastic polyurethane pre-heated in a moulded perimeter, ensuring flexibility and leak-free creases around corners and bends, followed by an ultrasonic edge weld, which binds all coatings and layers together for abrasion resistance and perimeter protection.

We can provide additional colourways, coating types, or fabric weaves upon request. Please keep in mind that custom cover fabrics will introduce minimum order quantities.

There is a 45€ fixed one-time surcharge for mould creation for non-standard armour cuts, regardless of size.

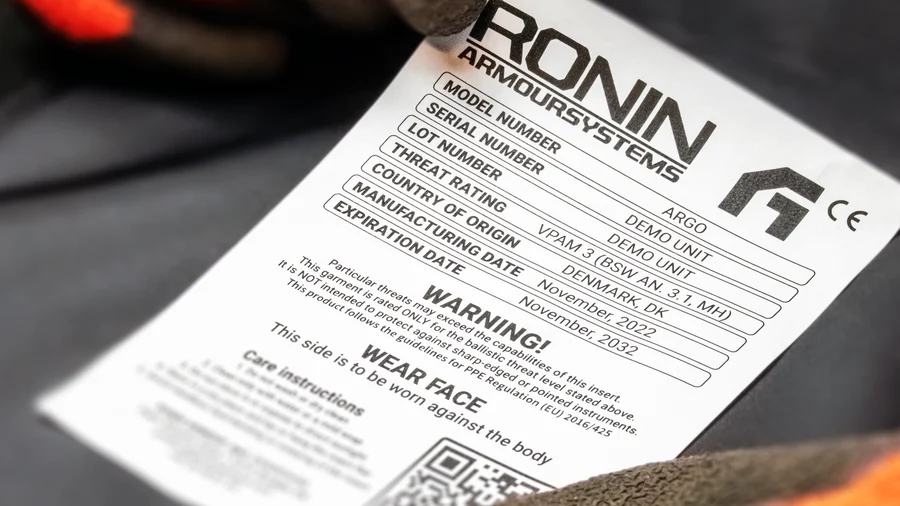

LABELING CAPABILITIES

We provide black-and-white labels on the front and back of any inserts free of charge. As standard, our labels adhere to the NIJ's label requirements and resist peeling, water, as well as isopropyl and denatured alcohol.

We can follow any LOT/SERIAL number identification system you use internally and link it with our internal LOT/SERIAL database for quality assurance. If not, we can provide LOT/SERIAL numbers with quality assurance and material tracking during insert manufacturing.

Please be aware that, ultimately, as a distributor of any OEM/ODM product, you will be in charge of final quality assurance.

For coloured label options, fees and minimum order quantities will apply.

TECHNICAL CUTTING DETAILS

We can natively process DXF, AI and (if set up correctly) SVG files, but if you have a schematic with noted dimensions, we can also digitise it for you at no additional charge.

Pricing is determined by the minimum or smallest enclosing box for the given shape(s) and is multiplicative of the area defined in square centimetres.

As an illustrative example, assume the sphere represents the armour cut. The striped orange square represents the total bounding box and determines the pricing.

When cutting multiple pieces, we use artificial intelligence to nest and optimise cuts, lower material waste, and ensure prices are kept as low as possible for any given shape.

UN-NESTED EXAMPLE

An example of an un-nested cutting job may appear as follows:

The example above has a 5830 cm² bounding box.

NESTED EXAMPLE

An example of a nested cutting job may appear as follows:

The example above has a 4490 cm² bounding box.

Using our proprietary nesting algorithm, we can decrease price and material usage by ~23% in this case. While we generally handle this when quoting, you may also freely opt to nest and optimise yourself, and we will carry out your cuts as they are defined.

READY TO GET STARTED?

If any of the above sounds like a fit for your brand or product idea, please get in touch with us to discuss it further!

Our product development department can be reached at the e-mail below:

OEM CONTACT

oem@roninarmour.com

Alternatively, you can get in touch with us using the B2B contact form at the bottom of our contact page and selecting "OEM/ODM Services" in the dropdown.