MADE IN DENMARK

Located in a small city on the edge of Southern Jutland in Denmark near the German border, we help keep a long-standing local craftsmanship tradition alive.

We pride ourselves on keeping our manufacturing in-house, focusing on quality, consistency, reliability, and a tremendous internal emphasis on keeping our personnel happy and satisfied to avoid mishaps and oversights.

We design, draft and produce all of our ballistic and non-ballistic soft products in our own facility that houses dedicated design, prototyping, cutting, drafting, sewing, sealing and packaging workshops.

MATERIAL SOURCING

Ballistic and trauma-mitigating materials are sourced exclusively from reputable partners and brands from Europe and the US, with material manufacturing located in those regions. Our primary ballistic material partners are Teijin and Honeywell, with anti-trauma materials produced by 3M Company and Propex.

All trademarks are property of their respective owners.

FABRICS & LAMINATES

Our fabric is sourced from within NATO exclusively, with most being manufactured in the US to adhere to the strict STANAG, TL and MIL-STD standards, with great care given to IR reflectivity profiles and durability.

Our tactical systems comply fully with STANAG 4370, meaning there is no risk of delamination in freezing climates or shifting in scorching ones.

PROCESSING & HANDLING

Our entire internal processing workflow is automated and optimised for consistency and reliability. We find this especially important for long-term durability, as single unevenly cut laminate layers may cause chafing against the cover material, leading to a breakdown of the cover or unwinding the ballistic fibers from their matrices, leading to performance degradations over time. Our CNC-operated material-cutting setup eliminates this problem altogether.

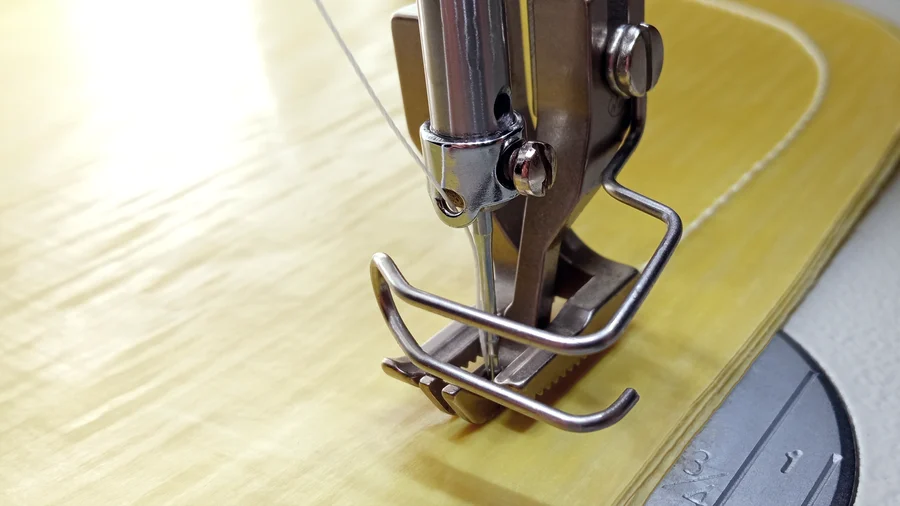

SEWING & FINISHING

We use powerful sewing machines capable of reliably lockstitching upwards of 40 layers of unidirectional ballistic laminate with appropriate multi-step bar tacking. We utilise 840dTex Twaron® and Dyneema® SK75 sewing threads with respective breaking strengths at 215 and 120 newtons for stitching our ballistic panels.

Finally, we label and seal the perimeter of the insert's cover in a pre-made mould to ensure flexibility and seam quality before ultimately ultrasonically cutting and welding all perimeter edges, ensuring durability for years to come.

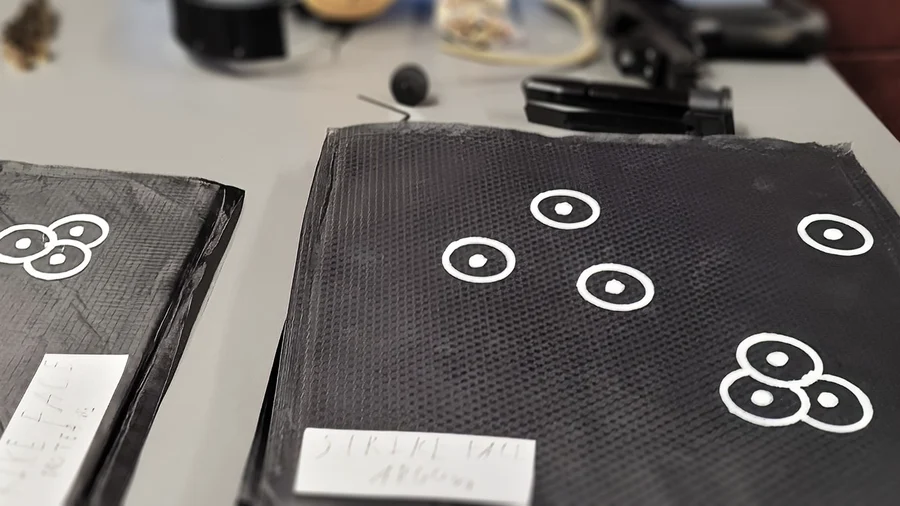

QUALITY ASSURANCE

After every operation within the manufacturing workflow, we perform a review step with a different operator in charge than the one who executed the operation.

All checkup criteria get noted and matched with the product's unique serial and lot number for later referencing if discover a product defect.

Furthermore, we rely on a network of partners who help us perform batch/lot testing of our ballistic products and screening services for our non-ballistic ones to ensure we maintain our quality standards for every product we ship.